A touchscreen is an electronic visual display that can detect the presence and location of a touch within the display area. The term generally refers to touching the display of the device with a finger or hand. Touchscreens can also sense other passive objects, such as a stylus. Touchscreens are common in devices such as all-in-one computers, tablet computers, and smartphones.

The touchscreen has two main attributes. First, it enables one to interact directly with what is displayed, rather than indirectly with a pointer controlled by a mouse or touchpad. Secondly, it lets one do so without requiring any intermediate device that would need to be held in the hand. Such displays can be attached to computers, or to networks as terminals. They also play a prominent role in the design of digital appliances such as the personal digital assistant (PDA), satellite navigation devices, mobile phones, and video games.

History

The first touch screen was a capacitive touch screen developed by E.A. Johnson at the Royal Radar Establishment, Malvern, UK. The inventor briefly described his work in a short article published in 1965[5] and then more fully - along with photographs and diagrams - in an article published in 1967.[6] A description of the applicability of the touch technology for air traffic control was described in an article published in 1968.[7]

Note: Contrary to many accounts,[8] while Dr. Sam Hurst played an important role in the development of touch technologies, he neither invented the first touch sensor, nor the first touch screen.

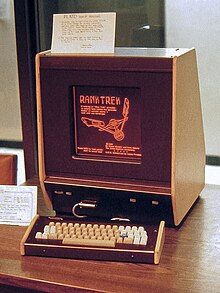

Touchscreens first gained some visibility with the invention of the computer-assisted learning terminal, which came out in 1972 as part of the PLATO project. Touchscreens have subsequently become familiar in everyday life. Companies use touchscreens for kiosk systems in retail and tourist settings, point of salesystems, ATMs, and PDAs, where a stylus is sometimes used to manipulate the GUI and to enter data.

From 1979–1985, the Fairlight CMI (and Fairlight CMI IIx) was a high-end musical sampling and re-synthesis workstation that utilized light pen technology, with which the user could allocate and manipulate sample and synthesis data, as well as access different menus within its OS by touching the screen with the light pen. The later Fairlight series III models used a graphics tablet in place of the light pen.

The HP-150 from 1983 was one of the world's earliest commercial touchscreen computers. Similar to the PLATO IV system, the touch technology used employed infrared transmitters and receivers mounted around the bezel of its 9" Sony Cathode Ray Tube (CRT), which detected the position of any non-transparent object on the screen.

An early attempt at a handheld game console with touchscreen controls was Sega's intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s. Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.[9]

Until recently, most consumer touchscreens could only sense one point of contact at a time, and few have had the capability to sense how hard one is touching. This is starting to change with the commercialization of multi-touch technology.

The popularity of smart phones, PDAs and tablet computers, portable video game consoles and many types of information appliances is driving the demand and acceptance of common touchscreens, for portable and functional electronics, with a display of a simple smooth surface and direct interaction without any hardware (keyboard or mouse) between the user and content, fewer accessories are required.

Touchscreens are popular in hospitality, and in heavy industry, as well as kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display's content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers worldwide have acknowledged the trend toward acceptance of touchscreens as a highly desirable user interface component and have begun to integrate touchscreen functionality into the fundamental design of their products.

Technologies

There are a variety of touchscreen technologies.

Resistive

Main article: Resistive touchscreen

A resistive touchscreen panel is composed of several layers, the most important of which are two thin, electrically conductive layers separated by a narrow gap. When an object, such as a finger, presses down on a point on the panel's outer surface the two metallic layers become connected at that point: the panel then behaves as a pair of voltage dividers with connected outputs. This causes a change in the electrical current, which is registered as a touch event and sent to the controller for processing.

Surface acoustic wave

Main article: Surface acoustic wave

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. This change in the ultrasonic waves registers the position of the touch event and sends this information to the controller for processing. Surface wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.[10]

Capacitive

Main article: Capacitive sensing

A capacitive touchscreen panel consists of an insulator such as glass, coated with a transparent conductor such as indium tin oxide (ITO).[11][12] As the human body is also an electrical conductor, touching the surface of the screen results in a distortion of the screen's electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Unlike a resistive touchscreen, one cannot use a capacitive touchscreen through most types of electrically insulating material, such as gloves; one requires a special capacitive stylus, or a special-application glove with finger tips that generate static electricity. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones.

Surface capacitance

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor's controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls andkiosks.[13]

Projected capacitance

Projected Capacitive Touch (PCT) technology is a capacitive technology which permits more accurate and flexible operation, by etching the conductive layer. An X-Y grid is formed either by etching a single layer to form a grid pattern of electrodes, or by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form the grid (comparable to the pixel grid found in many LCD displays).

The greater resolution of PCT allows operation without direct contact, such that the conducting layers can be coated with further protective insulating layers, and operate even under screen protectors, or behind weather and vandal-proof glass. Due to the top layer of a PCT being glass, PCT is a more robust solution versus resistive touch technology. Depending on the implementation, an active or passive stylus can be used instead of or in addition to a finger. This is common with point of sale devices that require signature capture. Gloved fingers may or may not be sensed, depending on the implementation and gain settings. Conductive smudges and similar interference on the panel surface can interfere with the performance. Such conductive smudges come mostly from sticky or sweaty finger tips, especially in high humidity environments. Collected dust, which adheres to the screen due to the moisture from fingertips can also be a problem. There are two types of PCT: Self Capacitance and Mutual Capacitance.

A PCT screen consists of an insulator such as glass or foil, coated with a transparent conductor – sensing (Copper, ATO, Nanocarbon or ITO). As the human finger (is also a conductor) touching the surface of the screen results in a distortion of the local electrostatic field, measurable as a change in capacitance.Now PCT used mutual capacitance, which is the more common projected capacitive approach and makes use of the fact that most conductive objects are able to hold a charge if they are very close together. If another conductive object, in this case a finger, bridges the gap, the charge field is interrupted and detected by the controller. All PCT touch screens are made up of an electrode - a matrix of rows and columns. The capacitance can be changed at every individual point on the grid (intersection). It can be measured to accurately determine the exactly touch location. All projected capacitive touch (PCT) solutions have three key features in common: • Sensor as matrix of rows and columns• Sensor lies behind the touch surface • Sensor does not use any moving parts.[14]

Mutual capacitance

In mutual capacitive sensors, there is a capacitor at every intersection of each row and each column. A 16-by-14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field which reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter. This method produces a stronger signal than mutual capacitance, but it is unable to resolve accurately more than one finger, which results in "ghosting", or misplaced location sensing.

[edit]Infrared

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any input including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and point of sale systems which can't rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system

No comments:

Post a Comment